Description

Handler introduces NEW technology specifically designed and engineered to support CAM milling applications. Model 100C under bench dust extraction system provides powerful 9 STAGE SUCTION to effectively remove dust from the chamber of the milling process. This extraction system can be used for dry milling on materials such as Zirconia, wax, PMMA, composite resin, PEEK, gypsum, porcelain, and glass fiber reinforced resin.

Dimensions:

100C – 11.3” W x 11.6” L x 19” H

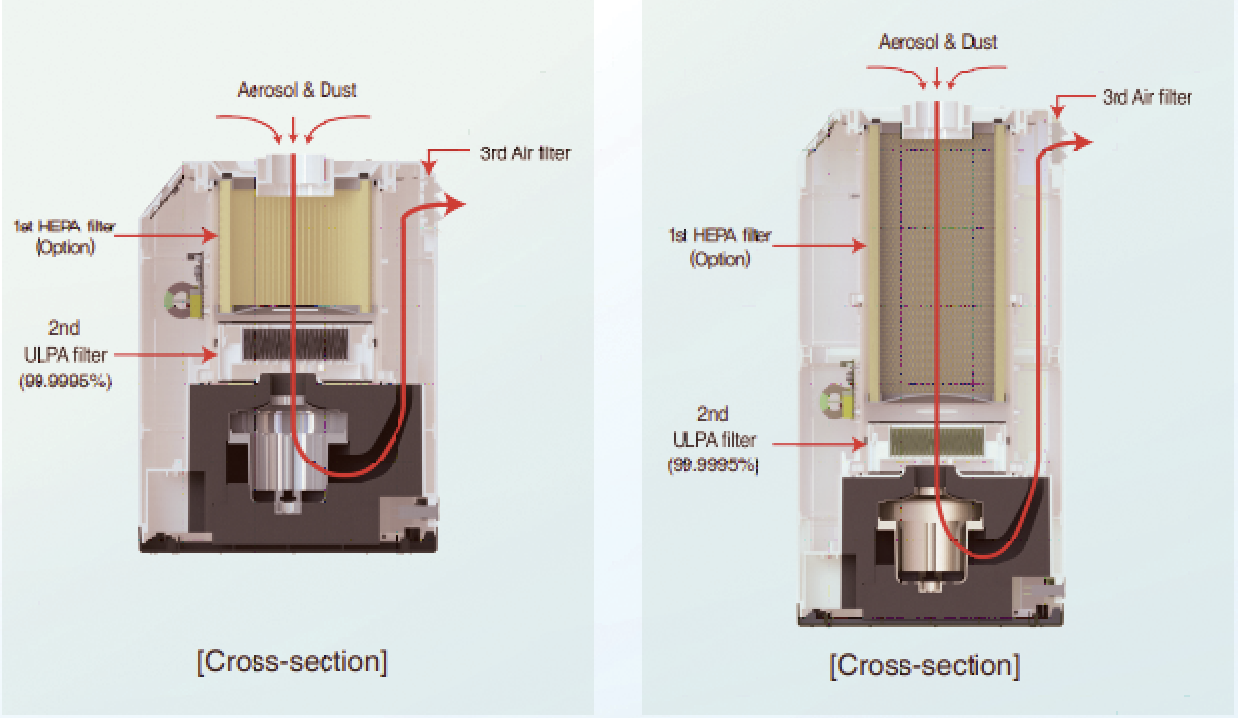

The machine will generate maximum air flow of 150 CFM (cubic feet per minute) and maximum air pressure of 23kpa or 3.34psi. Triple filtration system consists of a 1st stage drum cartridge HEPA filter, 2nd stage ULPA filter (99.9995% up to 0.12 um) and 3rd stage air filter for maximum protection and clean work environment. The machine comes complete with motor, digital keypad control with filter replacement indicator, triple filtration system, suction hose, factory installed castors with locks, CAM cabling interface and power cord. Accessories and optional CAM cabling is available. Some assembly required and may need adaptors to secure the suction hose to the milling machine.

The filter replacement notification informs you when to replace (clean) by measuring the pressure in the suction part by the pneumatic sensor. Also, the replacement (cleaning) cycle of the filter may vary depending on the usage. It is recommended to change the 3rd filter together when replacing the 1st filter.

Comes with cabling to connect to your mill (must specify your milling machine make and model in checkout page, order notes.)

The machine operates at 100V – 120V, 50/60Hz, 1200W +/-5%, single phase AC plug, 5.2A, 55dB. Unit weight is 30 pounds.