Description

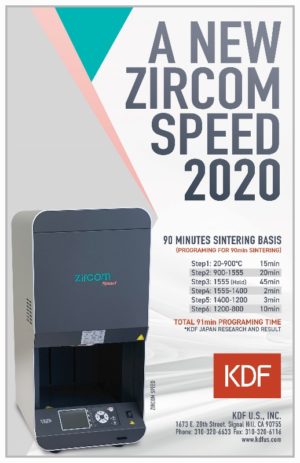

These high-temperature furnaces are ideally suited for sintering bridges and crowns made of translucent zirconia. The special heating elements made of molybdenum disilicide promise the best possible protection against chemical interaction between the charge and the furnace components. The bridges and crowns are loaded in ceramic saggars. These high-temperature furnaces are particularly convincing due to their excellent price-performance ratio. The furnaces can be individually programmed for all recommended sintering curves by almost all zirconium manufacturers

Includes Starter Set: 1 Regtanular tray and lid

- For translucent Zirconia

- Max Temp 1650°

- Special heating elements made of molybdenum disilicide offer best possible protection against chemical interaction between charge and heating elements

- Only fiber materials are used which are not classified as carcinogenic according to TRGS 905, class 1 or 2

- Dual Shell Housing with additional fan cooling for low surface temperature

- Adjustable air inlet

- Exhaust air opening in the roof

- Type S thermocouple

- Precise temperature control, also in the lower temperature range for drying

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller with memory for 50 programs

INNER DIMENSIONS: W110mm x D120mm x H120mm (4.3″x 4.7″ x 4.7″)

OUTER DIMENSIONS: W385mm x D425mm x H525+195 mm (15.2″ x 16.6″ x 20.6″ + 7.6″)

WEIGHT: 28 kg (62 lbs)

CONNECTED LOAD: 2.2kW

ELECTRICAL CONNECTION: Single-Phase

VOLTAGE REQUIREMENT: 220-240

Crated and ships via freight truck – Additional shipping charges apply

Call to order: 800-227-8524